chainflex® - 적용 사례

긴 사용 수명의 chainflex®.

고객을 위해 생산을 지속해야 하며 그에 따라 에너지 공급 장치가 원활하게 동작해야 합니다. 사용된 모든 부품과 케이블의 성능을 쉽게 달성할 수 있음을 전제로 합니다. igus®는 전체 e-chain system®을 개발한 최초의 기업이었습니다 chainflex® 케이블 및 e-chain® 은 용도에 따라서 한 공급자로부터 공급되며 시스템을 보증합니다. 전 세계적으로 기계 가동중단을 방지하는데 도움이 되는 설계 원리가 도입되어 1989년 이후부터 성장한 케이블의 노하우 및 많은 노력을 요하는 실험으로부터 발전을 거듭하고 있습니다.How chainflex® special cables keep a palletising system running

15 years maintenance-free: How special cables keep a palletising system running - The energy supply system from igus covers 73 million double strokes without a cable failure and breaks all records in the process!How chainflex® special cables keep a palletising system running

Flexible e-chains and cables for grippers in BD Rowa picking systems

In this automated warehouse, the company relies on our chainflex cables and energy chains for the highly mobile grippers.Flexible e-chains and cables for grippers in BD Rowa picking systems

Energy chains and cables for fail-safe storage and retrieval units

chainflex special cables and plastic energy chains are used in these automated and highly flexible storage systems from viastore SYSTEMS GmbH.Energy chains and cables for fail-safe storage and retrieval units

멀티 스핀들 선반에 사용되는 에너지체인

이탈리아의 Gildemeister Italiana S.p.A.가 멀티 스핀들 선반으로 vector 금상을 받았습니다.Multi-spindle lathes

chainflex® 열 보상 케이블을 사용한 혁신적인 연결 기술

MS Spaichingen은 혁신적인 연결 기술을 위해 chainflex® 열 보상 케이블을 사용합니다.chainflex® 열 보상 케이블을 사용한 혁신적인 연결 기술

Maintenance platform

Maintenance platform for WKA rotors, equipped with maintenance-free products from igus.Maintenance platform

chainflex® cables with insulation displacement technology

Permanent connection - Tried and tested: Insulation displacement connection technology (IDC) in movable cable systems from igus® & HARTINGchainflex® cables with insulation displacement technology

Torque-resistant cables for vertical order pickers of up to twelve meters

To avoid corkscrews, chainflex signal and power cables supply the logistics specialist Still's lift frames, which can be extended up to twelve metres.Torque-resistant cables for vertical order pickers of up to twelve meters

Tested cable/connector combinations

Tested cable/connector combinations increase the safety of machinesTested cable/connector combinations

IMAGIC flex drilling systems

The hybrid cables of the chainflex® product range are tried and tested and used in the new flexible IMAGIC flex drilling systems.IMAGIC flex drilling systems

Chip card readers

Special, high tensile strength bus cables for chip card readers in a lift system.Chip card readers

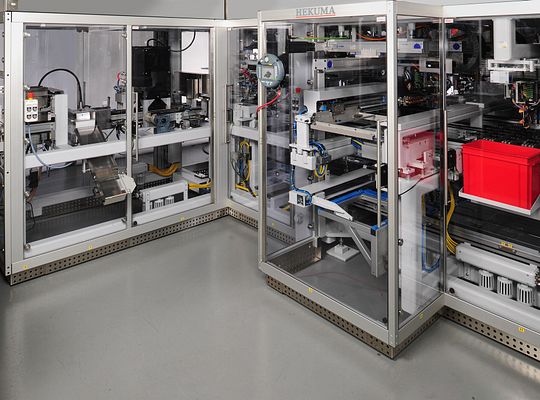

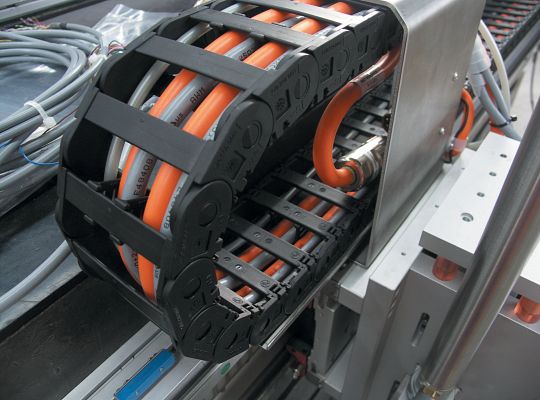

High-speed injection moulding machine

Hekuma has been using chainflex control cables and E6 energy chains in its high-performance injection moulding machines for the plastics industry for over 10 years.High-speed injection moulding machine

고성능 케이블 시스템

chainflex 케이블과 MFP8 RJ45 플러그 커넥터의 조합은 수백만 사이클 이후에도 뛰어난 전송력을 제공합니다.고성능 케이블 시스템

Special cables and e-chains for SMD pick and place machines

The chainflex cables tested in the largest laboratory for moving cables have proven themselves in over 400 million strokes in pick and place machines for circuit board assemblySpecial cables and e-chains for SMD pick and place machines

대규모 가공 센터

이구스의 측정 시스템 케이블도 장거리 신호를 안전하게 전송하므로 높은 기계 가용성을 보장합니다.대규모 가공 센터

Filling unit

No more malfunctions when dosing fluids with precision.Filling unit

Solar energy on a sailing boat

For protection against outdoor influences the connection cables of the solar cell were mounted in an E2 micro energy chain.Solar energy on a sailing boat

Cables and energy chains for circuit board assemblers

chainflex control and servo cables and E2 energy chains extend maintenance intervals in circuit board assemblers for the computer and automotive industry.Cables and energy chains for circuit board assemblers

Concrete manufacturing

chainflex® control cables significantly reduce the failure rate of the machine in the concrete factory.Concrete manufacturing

LED screen

Temperature-resistant chainflex® cables in an LED screen.LED screen

Sewage treatment plant

Energy chain system instead of cable drum - Smooth operation at the sewage treatment plant since 2000Sewage treatment plant

Passenger compartment doors

Control cables for extremely small bend radii in the passenger compartment doors in public transport vehicles.Passenger compartment doors

Stacking unit

300,000 double strokes a month impose rigorous requirements on the control cable.Stacking unit

Composting plant

Heat, abrasive dirt, high atmospheric moisture: These are only some of the ambient conditions in a composting plant.Composting plant

가구 공장

곡률 반경이 높은 케이블은 가구 산업에서 기계 가용성을 높입니다.가구 공장

Wood industry

The igus® preassembled energy chains create a lasting, low-wear connection to the tools.Wood industry

Lathe and grinder with durable energy chains

Top condition even after 9 years - Preassembled energy supply systems for precision machines working under tough environmental conditionsLathe and grinder with durable energy chains

Completely pre-assembled energy supply for gondola lift in fairground ride

Robust, safe, UV-resistant: A pre-assembled energy chain ensures the power supply to the lift at the funfair as well as quick set-up and dismantling.Completely pre-assembled energy supply for gondola lift in fairground ride

Safe cable guidance for 12 STS cranes at high travel speeds

Crane travels up to 500 m with energy chain systems and cables from igus®.Safe cable guidance for 12 STS cranes at high travel speeds

Streetcar switches

The applied material repels chips with temperatures up to 850° C without leaving a trace.Streetcar switches

Loading and unloading facility

Rigorous requirements imposed on the energy supply: Cycle times and narrow bend radii are a considerable strain on energy supply and lines.Loading and unloading facility

Wood and sandwich processing

Here an energy supply system was developed from standard parts, whose piggyback system at last allocates adefined place for the large volume suction hoses.

Wood and sandwich processing

Quickly installed energy chain in a Waldrich Coburg gantry milling machine

Pre-assembled energy supply systems for machine tool construction saved several weeks of assembly time in this application.Quickly installed energy chain in a Waldrich Coburg gantry milling machine

Robust cable guidance for dynamic Bystronic laser cutting machines

Because of the extremely high demands on dynamics and the high lateral accelerations, the energy chain has to be stable, robust, and not too heavy.Robust cable guidance for dynamic Bystronic laser cutting machines

Tailored energy supply for indoor cranes on a 32m long crane runway

The operator opted for energy chains for this indoor crane. They enable high flexibility, variability and space-saving installation.Tailored energy supply for indoor cranes on a 32m long crane runway

Energy supply system on shipyard crane: Functionally reliable despite typhoon storms

Energy supply systems for shipyard cranes successfully in operation since six years.Energy supply system on shipyard crane: Functionally reliable despite typhoon storms

Roller energy chain on ship unloaders over 400m travel

On a 441.3 m travel, a roller energy chain reduces the drive power by 75%Roller energy chain on ship unloaders over 400m travel

Energy chain at the bulk goods ship loader in the Baltic Sea port of Wismar

Since the ship loader started operations in 2000, no troubles, either mechanical or in the cables, have occurred in the energy chain area.Energy chain at the bulk goods ship loader in the Baltic Sea port of Wismar

Glass production

Higher variability at lower costs - Multidimensional energy supply systems raise the performance of robots.Glass production

Handling system

Robotic handling system for circuit boards. Flexible energy supply system in use in clean room technology.Handling system

OpenHydro tidal turbine

A plastic chain makes any kind of maintenance on the open sea obsolete; a conventional metal chain would not be adequate for the combination of technical, climatic and mechanical requirements.OpenHydro tidal turbine

Dummy robot

A very high acceleration provided an enormouschallenge for the design engineers of this robot.Dummy robot

TV - production

Highly flexible chainflex® control cables in TV production.TV - production

Low-floor tram

Operational safety in low-floor vehicles thanks to chainflex® control cable for extremely small bend radii.Low-floor tram

Machine building

The technical demands on energy supply systems in machinery and plant construction require cables that work reliably.Machine building

Special machine construction

Energy supply systems demonstrate their reliability even in particularly aggressive environmental conditions in special-purpose machinery construction.Special machine construction

Cable for USB interface

Because of their robustness and signal quality, chainflex bus cables are used in the USB interface for cameras from IDS GmbHCable for USB interface

Resilient energy supply systems and cables for linear drive technology from HIWIN

Energy supply systems and cables for the highest demands in linear drive technology.Resilient energy supply systems and cables for linear drive technology from HIWIN

Electric go-cart

Conversion of a go-cart with combustion engine into an electric go-cart with maximum driving pleasure.Electric go-cart

Indoor and outdoor cranes

Outdoor cranes must withstand harsh weather conditions. Indoor cranes also work under alternating moisture influences with simultaneous extremely high temperatures.Indoor and outdoor cranes

Conveyor unit of coal excavator

The winner of this year’s golden vector is also the longest travel ever to be realised with plastic energy chains in the world.Conveyor unit of coal excavator

Multi-axis robots

Maintenance free with cables and multi-dimensional energy chains.Multi-axis robots

chainflex CASE application

Simply saved in storage costs, delivery costs and process costschainflex CASE

Dumper

Clever solution for dumpers exposed to heavy loadsigus products in an AUSA dumper

Light-rail doors

Here's why igus components are especially well-suited to limited installation spaceCompact passenger doors for new light rail vehicles