완전 자동화된 커피 머신을 위한 3D 프린팅 - 자동화된 컵 트레이 조정을 위한 긴 서비스 수명

- What was needed: Components for the mechanism of an automatic cup tray adjustment for a fully automatic coffee machine

- Manufacturing method: Selective laser sintering

- Requirements: Food conformity, strength, stability, good operation properties, dimensional accuracy

- Material: iglidur I6

- Industry: Vending machinery

- Success from the collaboration: High abrasion resistance, toughness, and long service life, food conformity according to FDA and EU 10/2011

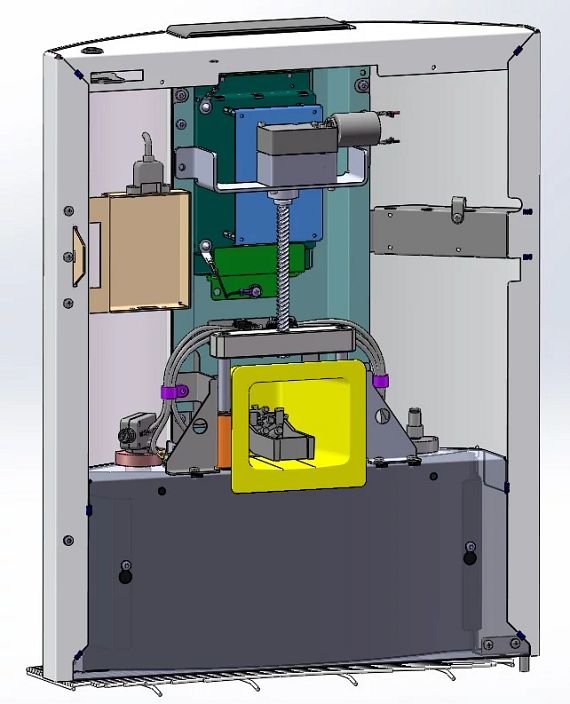

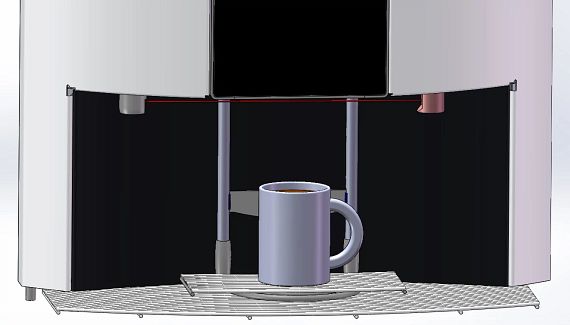

Until now, the fully automated coffee machine cup tray was adjusted to the cup size by hand. To fully automate tray adjustment, the project team from Maschinenbauschule Ansbach, a mechanical engineering educational institution, developed a motor-driven moveable cup tray with sensor-controlled height adjustment. The height adjustment mechanics used a motor, a 3D printed shaft end support, and a 3D printed lead screw. The 3D printed parts made of the iglidur I6 high-performance polymer have excellent operating properties, stability, and service life. The tribologically optimised plastic is also food-compliant according to FDA and EU 10/2011.

3D 프린팅 서비스로 이동

문제

지금까지는 커피머신 컵 트레이의 높이를 수동으로 컵 크기에 맞춰 조정했기 때문에 전자동 솔루션이 필요했습니다. 완전 자동 커피 머신의 컵 트레이 높이 조정을 자동화하기 위해 기계 공학 학교 Ansbach의 프로젝트 팀은 센서와 모터 구동 메커니즘을 개발했습니다. "샤프트 엔드 서포트 - 스핀들"의 적합한 재질을 찾아야만 했습니다. 이 재질은 샤프트 끝단 지지대와 스핀들 사이에 우수한 작동감과 커피 머신 내부의 치수를 충족하는 치수 정확도를 가져야 했습니다. 동시에 소재는 식품 접촉 및 컵의 전체 중량에 적합해야 했습니다.솔루션

프로젝트 팀은 쾰른의 igus GmbH에서 완벽한 파트너를 찾았습니다. 적층 제조 책임자인 Tom Krause와 협력하여 연구팀은 먼저 3D 프린팅을 통해 기계적 개념의 프로토타입을 생산하는 데 성공했습니다. 여기에는 igus가 레이저 소결을 위해 특별히 개발한 고성능 폴리머 iglidur I6이 사용되었습니다. 특히 높은 안정성, 치수 정확도 및 작동 특성으로 연구팀을 설득했습니다. 컨셉을 수정하고 개선한 후, 이구스의 3D 프린팅 서비스를 요청해 "샤프트 엔드 서포트-리드스크류"의 모든 구성 요소를 주문했습니다. 위에서 언급한 사양 외에도 연구팀은 FDA 및 EU 10/2011에 따른 높은 내마모성, 세부 수준 및 식품 적합성에 깊은 인상을 받았습니다. 또한 레이저 소결 공정에 도구가 필요하지 않고 최소 주문량 없이 효율적으로 부품을 생산할 수 있다는 점도 큰 도움이 되었습니다.자동 컵 트레이 조정 작동 방식

완전 자동 커피 머신이라는 용어는 주로 완전 자동화된 커피 준비 과정을 나타냅니다. 지금까지 컵 트레이의 높이는 다양한 컵 크기에 맞게 수동으로 조정되었습니다. 완전 자동화된 커피 머신이 그 이름에 합당한지 확인하기 위해 Ansbach 기계 공학 학교의 프로젝트 팀은 자동 컵 트레이 조정 시스템을 개발했습니다. 센서를 사용하여 높이를 조정한 다음 3D 프린팅된 스핀들과 샤프트 엔드 지지대로 구성된 레버 암에 부착된 전동 메커니즘을 움직이도록 설정합니다. 센서는 컵의 위쪽 가장자리와 음료 배출구의 아래쪽 가장자리 사이의 거리를 측정하고 투명 컵과 불투명 컵을 모두 인식합니다. 그런 다음 소프트웨어를 사용하여 정의된 거리에 도달할 때까지 모터를 제어합니다.

iglidur I6 - 식품 적합성 고성능 폴리머

마찰에 최적화된 폴리머 iglidur I6이 사용되었으며, 내마모성이 매우 뛰어납니다. 스핀들과 샤프트 엔드 지지대 사이의 동작은 프로젝트 팀이 이구스를 선택하게 만든 결정적인 요인 중 하나였습니다. 특히 벤딩 머신에 있어 이구스가 공급하는 재질은 특별합니다. 통합된 고체 윤활제 덕분에 외부 윤활이 필요하지 않습니다. 무엇보다도 FDA 및 EU 10/2011에 따라 위생성 인증 및 식품 접촉이 가능합니다. 레이저 소결을 위해 특별히 개발된 이 재료는 기존 플라스틱보다 수명이 훨씬 더 깁니다.iglidur I6 더 알아보기

iglidur I6에 대한 식품 적합성 선언(FDA)(PDF)